Guillotines are some of the most overlooked pieces of machinery in the plastics industry, but their benefits far outweigh their cost. Here at Arlington Machinery, we sell used and refurbished equipment from guillotines to extruders, all at fair prices. On top of the value of used machinery, an in-house guillotine can help you cut labor costs, reduce risk, and produce more; instead of a laborer carefully cutting a roll of material by hand, which comes with its own risks and is highly time-consuming, a guillotine can get the job done faster, safer, and cheaper. Most of our clients find that their guillotine pays for itself in just a few months. If you’re considering adding a guillotine to your facility or upgrading your current setup, Arlington Machinery can help. Our vast inventory of used plastics machinery can take your operation to the next level, at your convenience and on your budget. Reach out today at (847) 956-7300 to speak with our expert staff.

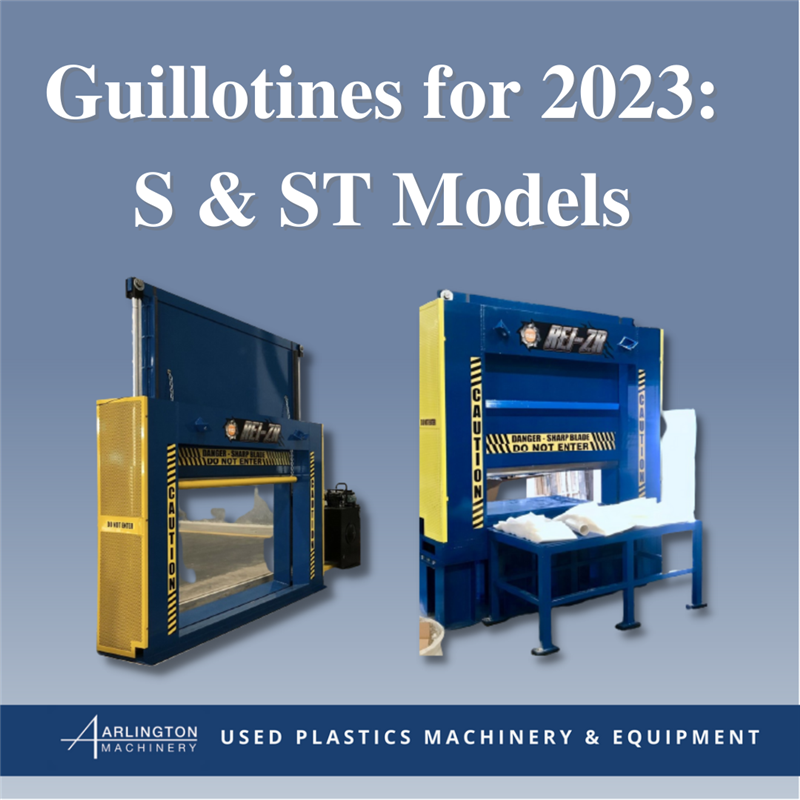

The basic structure of the guillotine is nearly uniform among manufacturers, but the latest models offer even more capabilities than older versions. Let’s take a look at two new models available at Arlington Machinery, the S model and the ST model.

The S Model

The most significant differentiators for the S model are its mounting options. This machine can be mounted above ground or set into a pit in-ground. Thanks to this installation and its size, users can roll or push loads into the action area, but that may create more work in retrieving the split materials once the guillotine has done its job. If your facility is set up to move loads from the floor such as with a forklift, the S model sounds great for you. If not, check out the ST model below for its unique setup and benefits.

The ST Model

The ST model is elevated on a tabletop for easier access to materials. This version includes a hydraulic loading and dumping table, which is essential for maintaining control over lighter materials or for directing heavier output into a loading bin. Unless your facility is set up to retrieve materials off of the floor, or you are planning to set it up in such a way, you’ll thank yourself for taking advantage of the tabletop option.

At A Glance

| S Model | ST Model |

|---|---|

| • Can be mounted on floor or in-ground | • Must be mounted above ground |

| • Ideal for smaller loads | • Ideal for larger loads |

| • Loads enter and exit on the floor | • Includes loading and dumping table |

Which Guillotine is Right for You?

Choosing a guillotine for your productions doesn’t have to be a challenge. With Arlington Machinery, you can shop our extensive collection of new and used guillotines and give us a call to learn more about the options available.

In order to select the right guillotine model, you need to answer three simple questions:

1. What are you planning to split?

What you plan to split will tell you the maximum size that your guillotine will need to fit. Most new models can handle loads 60 to 130 inches in diameter, which can be found under the unit’s specifications on each product page.

2. Is that material heavy or light?

The material type will dictate whether you need a hydraulic loading and dumping table. The heavier the load, the more likely you will need the table to direct output into an appropriate bin for mobility. If your load is lighter, you may not need this feature. Materials that are lighter or more brittle fall into the middle of the dilemma, but don’t fret—Our specialist team can help you make this decision with a simple phone call.